FAQs About Sealant & Caulk ▶

Sealants are materials that block the passage of fluids, air, insects, dust, sound, and heat through surfaces and mechanical joints. There is a wide range of sealants available in the market. Sealants and caulks can stick to materials such as concrete, wood, metal, glass, and fiberglass. Acrylic, polyurethane, and silicone sealants are among the most valuable options, thanks to their properties and area of usage.

What Is Sealant?

A sealant is a material that adheres to two or more substrates, preventing moisture, gases, dust, and other material from leaking through. It is also knowns as caulking and usually has a polymeric foundation. Sealants frequently contain diblock polymers to reduce viscosity, or solvency-based sealants can have a higher solid content. Besides that, a sealant might also comprise fillers and pigments, resin and adhesion promoters, plasticizers, protective chemicals, and curing agents.

Sealants remain on surfaces they are applied due to their no-flow feature. There is usually a lifetime warranty on sealants, regardless of their quality, which gives the user a new sealant in exchange for the defective one. The use of sealants is common in the industry to cover openings that cannot be covered by drywall or concrete. Solvent-based sealants are generally preferred in the construction industry and may be weak, strong, rigid, permanent, or temporary.

3 Types of Sealants

The modern construction industry relies heavily on sealant joints in lightweight masonry walls, rain screens, renders, and curtain walls to provide air and weather seals and to accommodate building movements such as thermal expansion, settlement, creep, sway, and differential slab edge deflections. And there are three main types of this reliable material: polyurethane, silicone, and acrylic.

Acrylic sealants accommodate UV-resistant features. They are convenient to use exterior usage and durable against shrinkage. However, applying this sealant may be hard due to its movement capability.

Polyurethane sealants stick well to a variety of surfaces without excessive preparation. They are well resistant to corrosion and shearing force. Therefore, contractors' first choice is usually polyurethane sealants. Also, the movement capability of this type of seal is high.

Silicone sealants have excellent thermal resistance and great dynamic movement capacity. But, they can easily break down and get dirty. In some cases, primers are required for specific substrates, such as stone, due to staining concerns. Silicones can be used structurally to bond glass and metal to frames, weatherproofing, and air sealing. They are usually the most expensive option, but quality ones have high durability.

Sealant Properties

It is important to consider the properties of the sealant you will use since it affects the area you will use it for. Here are the most significant properties you need to consider:

- Consistency: High viscosity sealants won't flow much from vertical joints, even if applied vertically. On the other hand, sealants with low viscosity can diffuse into an underlayer. They are self-leveling and used in horizontal joints.

- Durability: Silicone sealants have the most extended lifespan, nearly 20 years. And acrylic sealants last a little more than five years. If the sealant is misapplied, it is impossible to reach the expected life span.

- Hardness: Hardness is the ability of resistance to deformation. The more hardness increases, the more flexibility decreases.

- Movement capability: It is stated as a percentage of the joint width. A sealant with a movement capability of 10% in a 25 mm joint can stretch to 28 mm or contract to 23 mm and still perform as intended.

- Modulus of elasticity: Low-modulus sealants have high movement capacity and are preferred for delicate substrates. For the cases of static or non-moving joints, usually, high-modulus sealants are preferred. Medium-modulus sealants are used for general purposes and to balance the strain at the surface.

- Adhesion: Manufacturers provide adhesion information with the product, or you can test it. It is an essential factor when choosing a sealant.

- Staining: It is recommended to test the sealant before using it because sometimes the components of the sealant can stain the substrate.

- VOC content: Sealants generally contain respiratory irritants that you need to avoid. But, manufacturers developed VOC content with fewer irritants. Nevertheless, you must take the necessary measure because some sealants still have high irritants.

- Ease of application: It is important to consider their curing and tooling characteristics when evaluating the ease of application of sealants. You should bear in mind that some sealants are designed to stay uncured.

- Weather resistance: High-performance sealants work well and resist extreme temperature, moisture, and sun. They can remain flexible.

- Cost: The price of a sealant varies depending on the product's performance and ease of application. It is better to choose the best sealant in the beginning because it is more expensive to replace a failed application.

What Is a Sealant Used For?

In general, the use of sealant purposes to close openings between surfaces. Sealants have three fundamental functions:

- To fill the gap between multiple components

- To provide a protective waterproof barrier

- To maintain a sealing property under provided service conditions

The application area of sealants has a wide range thanks to their essential functions. It can be applied around the rough opening by window and door installers to create an airtight seal. Additionally, sealants may be used for window glazing, repairing cracks in concrete foundations such as walls and sidewalks, repairing seams around moldings within the home, and repairing sink drains and bathtub surrounds. Using sealants for wood and RV roof is also among the typical application areas.

How to Pick the Best Sealant?

Choosing the best product, in the beginning, saves you from future expenditures. The properties of the sealant are the most important factor when selecting a product. Also, the type of sealant is important as the application area changes. They need to match the requirements of the surface and the use of purpose.

In Case of Fire Rated

Akfix AC607 fire-rated acrylic sealant is ideal for sealing joints in compartment walls and floors to prevent flammable gases from passing through. In specific cases, it can resist fire for more than 4 hours with no backfilling materials. It is easy to apply, paintable, flexible, and non-slump. It can seal areas, seams, and areas where fire resistance is mandatory.

In Case of Wet Areas

918N Neutral Sanitary Silicone is a one-component, high-quality moisture-curing neutral silicone sealant designed for sanitary applications where non-corrosive, mold-proof, and chemically resistant properties are required. It is suitable for sealing connection joints between various substrates in wet areas.

For Kitchen & Bathroom Projects

100S Sanitary Kitchen & Bathroom Silicone has the property of acetoxy cure, high performance, mold-proof silicone sealant designed for gap filling and sealing in a wide range of sanitary applications. It has a low modulus with high elasticity and does not contain any solvent. It is resistant to the sun, rain, snow, and ozone. Therefore, it does not crack.

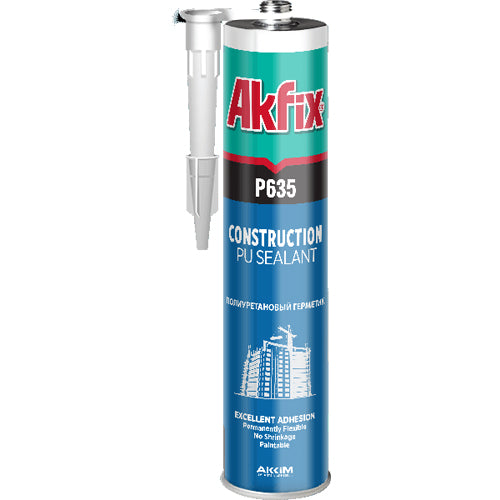

For Construction Projects

P635 Polyurethane Sealant Construction is a one-component, low-modulus polyurethane sealant that cures exposure to atmospheric humidity. It possesses excellent adhesion to all typical construction materials such as cement-based materials, brick, ceramic, glass, wood, galvanized and painted sheet iron, and various plastics.

For Diverse Projects

Akfix Multi-Seal is a universal grade, general purpose all-weather adhesive sealant based on AST polymer. It combines silicone and polyurethane properties, making it an optimum choice for Akfix Multi-Seal, a variety of substrates including aluminum, granite, ceramics, marble, porcelain, metals, PVC, glass, wood, porous surfaces (concrete, brick, limestone, etc.).

For Low Cost & Environmentally Friendly Projects

AS606 is a one-component acrylic emulsion-based sealant reinforced with silicone emulsion. It has superior adhesion and good elasticity. It has a non-toxic property thanks to its water-based formula. In addition, the AS606 sealant is paintable and easy to apply. Application areas include various construction materials, joints between windows and walls, doors, and ceilings.

FAQs For Sealant

Is Silicone the Same as Sealant?

In a short answer, no. Silicone is not the same as a sealant. Sealant is a broad term describing chemicals used to seal. On the other hand, silicone is a type of sealants like acrylic sealants or polyurethane sealants. Moreover, silicone has different uses, such as plastic surgery or computers.

What Sealant to Use on RV Roof?

Acrylic sealant is formulated to protect and add durability to RV roofing surfaces. When it becomes cured, it reflects heat and light and, thus, helps to keep your roof's surface cooler. Acrylic sealants are the most affordable product for RV roofs.

A polyurethane sealant resists UV rays, picks up dirt, and maintains its color for extended periods. They are flexible and durable and have better adhesion and UV resistance.

Silicone sealants have great reflectivity, and they are resistant to wind degradation. Silicone sealants are better than acrylic and polyurethane sealants to resist ponding water. Also, they stay extremely elastic.

How to Remove Sealant?

Applying a sealant remover is an effective and easy way to remove the sealant. However, you should wear gloves and a mask for protection. After applying the remover, wait for 3 hours. Then, you can scrape away the sealant with a plastic tool or a knife. And when you remove it, you should clean the area with warm water. Lastly, remember to dry the area before applying the new sealant.

Is Sealant Toxic?

Sealants may contain toxicants. However, it is possible to avoid their toxicants by preferring the right product. Here are what you should be careful about:

- Choose products with low VOC value.

- Prefer water-based sealants because they are the least toxic options.

- Beware of health-harming ingredients such as petroleum solvents, ethylene glycol, isocyanates, formaldehyde, phthalates, bisphenol A, or BPA.

- Use solvent-free silicone sealants for wet interior areas such as sinks and bathtubs.

- Applypolyether-based sealants for exterior places since they do not contain carcinogens and are less harmful.

Is Sealant and Caulking the Same Thing?

Caulks and sealants are applied to fill the gaps and cracks between building materials. And both are usually used by a caulking gun. Therefore, these two products are assumed to be the same. However, there are some basic differences.

Elasticity is the key difference between caulk and a sealant. Sealants are made of an elastic substance like silicone. It makes the sealant ideal for areas prone to expansion and contraction. When caulk dries, it has a more rigid form than sealants. That is why caulks are used in areas where minimal expansion is needed.

Is Silicone Sealant Paintable?

When you paint the sealant, it will repel the paint since it is a water-based sealant. Therefore, if you want to paint silicone sealant, you must use oil-based paint. If this method does not work, you can engrave the silicone with the help of sandpaper so that the paint has more surface to stick.

Do Silicone Stop Leaks?

With a short answer, yes, silicone stops leaks. Silicone sealants are particularly effective in plumbing applications because they are waterproof and offer elasticity and stability in high and low temperatures. Silicone sealants to use for plumbing are available in tubes and cartridges.